Digital printing has emerged as a leading technology in the printing industry, offering several advantages over traditional methods. As businesses and individuals increasingly seek high-quality, efficient, and cost-effective solutions, choosing between digital printing and traditional printing methods becomes crucial. This blog will explore the key differences between these two printing methods, focusing on print quality, cost and eco-friendliness.

Printing Progress Ltd stands out as a trusted provider of print and digital printing techniques, offering businesses a wide range of services that cater to every need. Our expertise and commitment to quality help bring your ideas to life with precision and excellence every time.

Call us on 0800 999 1094 or drop us an email at info@printingprogress.co.uk to enquire about our printing services.

Looking for expert digital and traditional printing methods for your business? Printing Progress Ltd. offers high-quality, customised printing solutions to meet your unique needs and help your business make a lasting impact.

What Is Digital Printing?

Digital printing refers to printing digital-based images or designs directly onto various media, such as paper, fabric, or other materials. Unlike traditional methods, there is no need for a printing plate, as digital print technology uses printers that apply toner or ink directly to the surface. This process can be done with CMYK printing techniques, allowing for precise and vibrant colour reproduction.

One of the primary benefits of digital printing is the speed of digital printing. Because it doesn’t require the setup of plates, it’s a faster and more flexible process, particularly suited for short print runs, personalised products, or on-demand printing. This makes it ideal for custom printing options and small businesses looking for high-quality prints without a significant upfront investment.

What Are Traditional Printing Methods?

Traditional printing refers to older processes used to reproduce images and text. The most common methods include lithographic printing (often known as offset printing), flexographic printing, and gravure printing.

1. Lithographic printing: In lithographic or offset printing, a design is transferred to a metal plate, which applies ink to paper. This method is widely used for printing books, magazines, and large volumes of paper materials.

2. Flexographic printing: Typically used for packaging materials, this method involves flexible printing plates to transfer ink onto the surface. It’s commonly used for printing on materials like plastic, cellophane, and other non-paper surfaces.

3. Gravure printing: This method uses an engraved cylinder to transfer ink onto a substrate, and it’s mainly used for high-volume production, such as newspapers and packaging materials.

Traditional methods often require extensive setup, including creating plates or rollers, making them more time-consuming and expensive for small print runs.

Print Quality Comparison: Digital Vs Traditional Methods

There are several factors to consider when comparing print quality and durability between digital and traditional printing.

Digital printing offers high-resolution prints and can produce vibrant colours with excellent detail, especially when using CMYK printing techniques. However, it may not match the sharpness or consistency of colours achieved with traditional methods like offset printing for large print runs. Digital print technology has improved significantly, and for many applications, the difference in print quality is hardly noticeable to the average consumer.

Traditional methods are more reliable for large volume runs in achieving consistent print quality across all materials. Lithographic printing is particularly praised for its ability to produce fine details and vibrant colours with superior print durability.

Are Digital Printing Methods More Eco-Friendly?

The environmental impact of any production process is essential in today’s world, and printing is no exception. Regarding eco-friendly printing, digital printing has certain advantages over traditional methods.

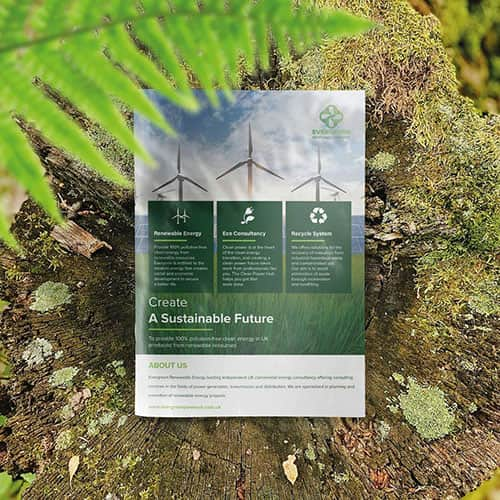

Digital printing is more energy-efficient because it doesn’t require plates or extensive setup, which leads to less waste. It also allows print-on-demand services, reducing the need for extensive inventories and minimising paper waste. Since digital printing uses liquid ink or toner, it tends to produce fewer chemical pollutants than traditional methods that use more hazardous materials.

Traditional printing, significantly offset printing, requires plates, ink, and large amounts of water for cleaning, which can result in higher levels of waste and energy consumption. While flexographic printing is more eco-friendly than other traditional methods, it still involves a fair amount of waste, solvents, and chemicals.

Hence, digital printing has a smaller environmental footprint, making it a more sustainable option, especially for smaller print runs or jobs that require frequent design updates.

Cost Comparison – Digital Vs Traditional Printing

The cost comparison between digital and traditional printing depends mainly on the volume of print jobs.

For small print runs, digital printing is the more affordable option. Since there are no setup costs for plates or rollers, digital print technology allows for more economical pricing for short runs, custom printing options, and on-demand services. It’s ideal for businesses or individuals who need a few copies or personalised prints, and it helps save money by avoiding wasteful overproduction.

On the other hand, traditional printing methods, like lithographic printing (offset printing), tend to be more cost-effective for large-volume print runs. The setup cost is higher due to the creation of plates, but once set up, the per-unit cost for large print volumes can be significantly lower than digital printing. This makes traditional printing methods better for mass-production projects such as magazines, books, and large commercial print jobs.

Future Of Printing – Combination Of Traditional And Digital Methods

The future of printing lies in the continued advancement of both digital printing and traditional methods. However, digital printing is poised to dominate the market with increasing demand for custom printing options, smaller print runs, and sustainability. Digital print technology innovations continue to improve quality and efficiency, making it a versatile choice for a wide range of applications. Print-on-demand services in the UK are also expanding, allowing businesses and individuals to print exactly what they need, when needed, with minimal waste.

This hybrid approach can combine the efficiency and customisation of digital print with the high-quality finish of traditional methods for large-scale production.

CONTACT PRINTINGPROGRESS

Get In Touch With Printing Progress Ltd!

Both digital printing and traditional printing methods have their advantages depending on the job’s specific needs. Digital printing offers flexibility, speed, and eco-friendliness, perfect for smaller print runs and custom jobs.

Meanwhile, traditional methods like offset printing excel in large-scale production, offering unbeatable consistency and high-quality results.

Printing Progress Ltd offers a comprehensive range of high-quality print and digital printing techniques to meet the unique needs of your business. Whether you’re looking for vibrant digital printing for small runs or traditional printing methods for larger volumes, we always ensure exceptional results. In addition to our printing services, we provide expert graphic design, illustrations, and branding solutions to help elevate your business’s visual identity. From custom packaging to professional stationery services, we work with you to create impactful designs that resonate with your audience.

Contact us for all your printing and design needs and let us help you bring your business vision to life with the highest quality and precision.

Eco friendly, sustainably sourced recycled FCS certified print

Eco friendly, sustainably sourced recycled FCS certified print Takeaway Screens

Takeaway Screens Postal Boxes

Postal Boxes