Have you ever picked up a glossy magazine, a thick catalogue, or a mass-mailed brochure and wondered how its pages maintain such consistent quality, even over thousands of copies? That’s often the magic of web offset printing at work. At Printingprogress, we use this method when durability, speed, and cost efficiency are essential to your project.

Do you need a specialist partner to determine whether web offset printing is the right fit for your next large print run? Call us on 0800 999 1094 or email info@printingprogress.co.uk — we’ll walk you through the options.

Printingprogress turns high-volume print runs into seamless, stunning realities — fast, reliable and beautifully crafted.

Why Web Offset Printing Matters (And What It Is)

Web offset printing is a variant of traditional offset printing where a continuous roll (web) of paper is fed through the press instead of individual sheets (sheet-fed). The image is transferred (offset) from plate to blanket cylinder, then onto the paper, which is why the results are incredibly sharp and colour consistent.

There are two primary forms: heatset (for coated, glossy jobs) and coldset (for uncoated, newsprint-style). At Printingprogress, we tailor which type to use depending on your project needs and paper type.

Because the paper is continuous, the process can run at very high speeds, making web offset printing ideal for large-volume projects such as magazines, catalogues, newspapers, brochures, and direct mail campaigns.

Key Benefits Of Web Offset Printing In Practice

Here are the primary advantages you get when choosing web offset with us:

- Cost-efficiency at scale: Since we use continuous rolls, the per-unit cost drops significantly for large runs.

- Lightning-fast throughput: Web presses can produce thousands of feet per hour, enabling us to meet tight deadlines.

- Consistent quality across the run: Colour, clarity, registration — everything stays stable from the first sheet to the last.

- Wide format and flexibility: Web offset printing handles long runs and large dimensions more effectively than sheet-fed printing.

- Paper options and economical weights: We can work with fine paper grades (e.g. ~49 gsm) or heavier stocks, depending on the job.

- Versatility for many formats: Ideal for magazines, catalogues, brochures, newsletters, free-standing inserts, and high-volume mailers.

When Web Offset Printing Is The Best Option

Here are scenarios when we recommend web offset printing as the optimal choice:

- You’re printing in the thousands or tens of thousands: If your project is a mass-market product, such as a monthly magazine or a national mailing, web offset printing is a cost-effective option.

- Tight deadlines and fast delivery matter: When you need to flood the market quickly, the speed advantage is critical.

- You require uniform colour consistency: For projects that must look identical from page to page and across years, web offset printing delivers.

- Brochures and catalogues with long page counts: Folding, binding, and finishing a multi-page piece is smoother with roll-fed printing.

- Low-cost, thin paper stocks are required: Certain thin or bulk-weight (economy) paper grades work better in web offset presses.

By contrast, for smaller runs (say under a few hundred copies) or when you need frequent design changes, digital or sheet-fed offset might be more economical. (We discuss that trade-off in our blog “Understanding Offset Printing And Its Applications”)

CONTACT PRINTINGPROGRESS

How We Run Web Offset Jobs At Printingprogress

When you choose us for web offset printing, here’s what you can expect:

- Pre-press checks & proofing: We review your files, check colour separations, bleeds, and safety margins — catching issues before they cost you.

- Plate & cylinder setup: For each colour (CMYK or more), we create plates and mount them carefully.

- Impression & ink control: The web runs continuously, with constant monitoring to maintain registration and ink balance.

- Drying and finishing: Depending on whether the print is heatset or coldset, the printed web may pass through drying/IR units before being cut, folded, or bound.

- Quality control through the run: We check random sheets from start to finish, ensuring no colour drift or faults.

- Delivery & logistics: With complimentary nationwide delivery (UK), we ensure your job reaches you intact, on time.

Conclusion

When your project demands speed, cost efficiency, and consistent quality over high volumes, web offset printing is often the most suitable choice. At Printingprogress, we’ve built our reputation on handling these demanding runs with precision, reliability and care.

Is web offset printing the right choice for your next project? Please call us on 0800 999 1094 or email us at info@printingprogress.co.uk. We’ll assess your brief, guide you through options, and deliver tailored quality that supports your brand.

FAQs About Web Offset Printing

1. What’s the difference between heatset and coldset web offset?

Heatset uses dryers and is ideal for glossy, coated jobs. Coldset is used for uncoated papers (e.g. newsprint) and doesn’t require drying ovens.

2. Can web offset printing handle variable data or customisation?

Not easily. Web offset is best for static content. For variable data printing (personalisation), digital printing is better suited.

3. Is web offset printing environmentally unfriendly?

Not necessarily. We use sustainable paper sources and inks when possible. The high efficiency of web offset also reduces waste compared to lower-volume methods.

4. How many pages can a web offset job support?

Really long ones — magazines, long catalogues or booklets are all feasible. The limitation is more about finishing than feed length.

5. What’s the minimum quantity for web offset to be cost-effective?

Typically, in the low thousands; below that, unit cost is too high vs digital or sheet-fed alternatives.

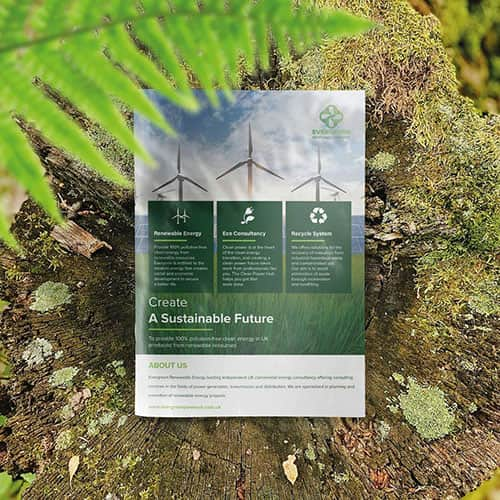

Eco friendly, sustainably sourced recycled FCS certified print

Eco friendly, sustainably sourced recycled FCS certified print Takeaway Screens

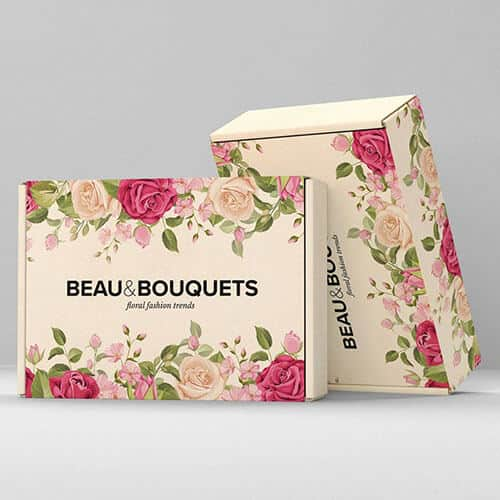

Takeaway Screens Postal Boxes

Postal Boxes